What is saddle stitching?

It is not uncommon to read the words "handmade", "handmade" or "handmade", highlighted by many leather goods brands. However, in the majority of cases, the sewing machine is used for the realization of seams. At Lamaro, no sewing machine, but the saddle stitch.

What is saddle stitching?

Saddlery stitching is the most widely used manual stitching technique in saddlery and leather goods. It is a centuries-old technique, originally invented for carriage parts, then later used in luxury leather goods. It is considered to be the strongest stitching available, and it is often said that leather will give way before it does! But one of its particularities is that it cannot be reproduced by a machine.

What are the differences between "machine" and "saddle" sewing?

It is not a question here of denigrating the so-called "machine" sewing, which requires a real know-how on the part of the leatherworker who uses it, but simply of pointing out the differences that exist.

The technical characteristics

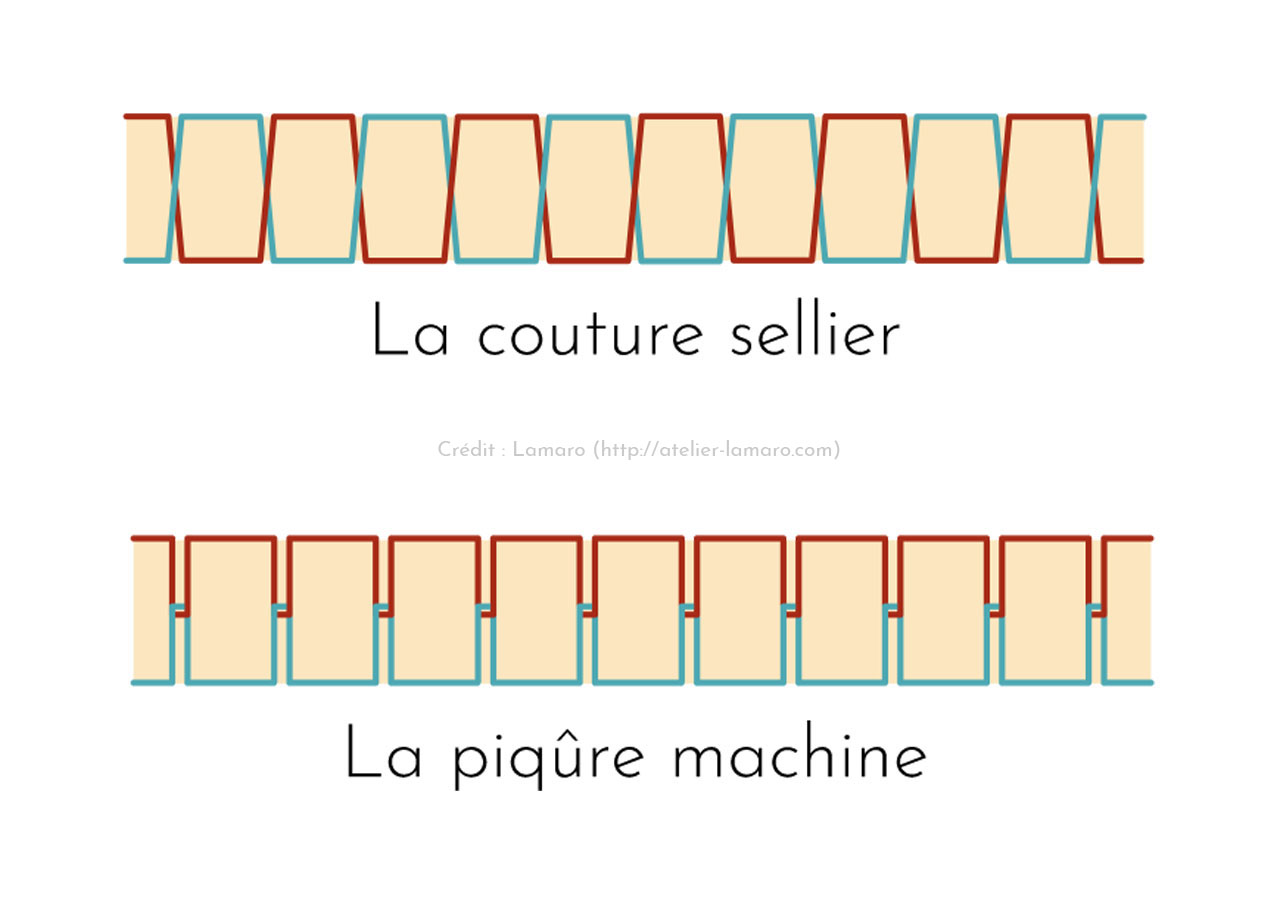

Saddle stitching is done with a single thread and two needles, one at each end of the thread. At each stitch, the part of the thread located above the piece to be sewn will pass to the bottom and the one below will pass to the top. The two parts of the thread cross each other in the material forming a knot (this is also often referred to as a laced saddle stitch), hence the extreme strength of this stitch. In other words, if the thread breaks at one point, the seam will not come apart.

In contrast, a sewing machine uses two threads: one for the top, one for the bottom (which can be different colours). The threads cross each other halfway through but always remain on their side, one holding the other. In this case, if a thread breaks, the seam is likely to come apart, since the second thread will no longer be held by the first.

The aesthetic characteristics

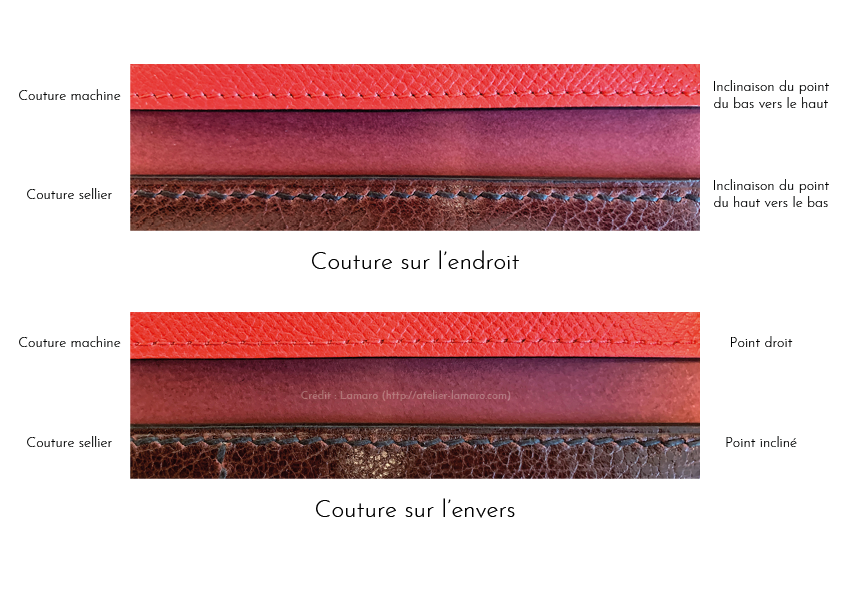

Beyond its solidity, the saddle stitch is also used for its aestheticism, a slightly inclined stitch, very recognizable. Nevertheless, a machine can be equipped with a diamond-shaped needle which makes it possible to carry out, at least on the front face, an inclined stitch close to the saddle stitch. This is the case for Hermès bags, which, contrary to certain preconceived ideas, are not entirely hand-sewn.

However, there are two ways to distinguish them, for the discerning eye:

-

On the right side: if you look at the seam horizontally, you will notice that the saddle stitching is slanted from top to bottom, while the machine stitching is slanted from bottom to top

-

On the reverse side: the saddle stitch has a nice slope, whereas the machine stitch is almost straight, which makes it less attractive

How is a saddle stitch made?

To make a saddle stitch you need a certain number of tools:

-

A dry point compass: it allows you to make a line parallel to the edge of the leather to make a straight and regular seam.

-

A punching claw: by following the line made with the compass, the claw allows to mark each stitch in advance.

-

A saddler's clamp: this large clamp, which the saddler-maroquinier wedges between his legs, allows to maintain the piece of leather so as to be able to sew with both hands (a needle in each hand).

-

An awl with pliers (or rhombus awl): its sharp blade in the shape of a rhombus makes it possible to pierce the leather without tearing it while preparing the slope of the point. Each perforation is made as the seam is sewn, following the marks made with the punching awl.

-

A round awl: this second awl is not sharp and will be useful in particular to increase the size of certain stitches, in order to make double stitches, without cutting the thread or the leather.

-

Two round point needles

-

Thread : at Lamaro, we use linen thread because it is a natural and very resistant fibre (to know more about the thread we use, click here).

-

Beeswax: in order to increase its resistance to friction, the linen thread is "poissed", i.e. it is waxed with beeswax

The dry point compass

The striking claw

The awl with clamps

If machine sewing is a much more economical choice, at Lamaro we have chosen to perpetuate ancestral know-how and to propose articles of great solidity and durability, manufactured according to the rules of the art. Now, the difference between these two practices has no more secret for you! You will be able to more easily understand the work that represents a piece of leather goods 100% handmade and hand-sewn. If you wish to discover more about our values and our manufacturing techniques, go to the"About" tab of our online store. Do not hesitate to ask any questions in comments, we will be happy to answer you.

You can also find the entire collection Lamaro by clicking here.

Your leather goods

feedback

No comments yet!

Leave your comment